Foaming Paint for Textile Printing

Basic Info

Model No.: ABC

Product Description

Model NO.: ABC Appearance: High Solid Method: Brush Certification: SGS Formation Mechanism: Non Conversion Type Packaging: Plastic Drum Trademark: kexun Specification: SGS Color: Light Yellow Main Raw Material: Acrylic Level: Primer Components: Auxiliaries Expiration Date: 1 year Style: Organic Pigment Transport Package: 20~30kg/Barrel...etc...Depend on Customer Origin: Guangdong, China (Mainland)

Foaming paste A;

Foaming paste B;

Foaming paste C.

I. Properties:

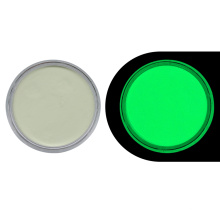

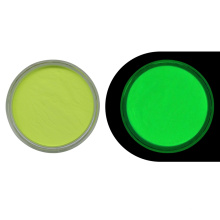

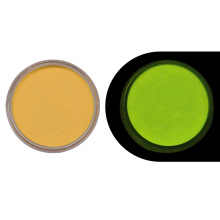

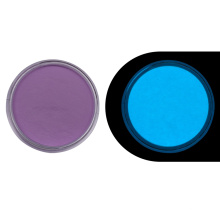

(1) Appearance: light yellow paste

(2) Composition: high molecular polymer and filling compound

(3) Ion type: Negative ion type or Non-ionic type

II. Characteristics

(1) Good foaming effect and excellent stereo sense

(2) Good fastness, soft hand feeling, flat surface

(3) Foaming height: A> B> C

III. Application scope:

It is suitable for printing bulge type pattern on cotton or cotton blended fabrics.

IV. Reference formula:

20 to 50 percent of foaming paste

30 to 40 percent of white glue

20 to 40 percent of elastic transparent glue

5 to10 percent of Pigment Paste

100%

V. Printing processes:

In order to create a better stereo sense, it is necessary to be over printed two times.

I.e.: Printingblow dryingprintingair drying (or baked under moderate temperature) hot pressingfoaming and shaping.

After foaming, it should have a flat surface; the hot pressed foaming pressed is carried out under a temperature of 130 to 150 also for about 5 seconds.

To have a brighter, more lustrous and more elastic effect, you can cover foamed patterns by a layer of overprinted elastic transparent glue mixed with coating.

I.e.: Foaming paste printingblow dryingprintingblow drying---transparent glue plus coating printingblow drying or baked under moderate temperatureheated to foam into final shape.

VI. Precautions:

(1) The printed patterns should not be heated for foaming before they completely dry, otherwise, the fastness and flatness will be affected.

(2) The foaming paste should be made too thin.

(3) Do not add water, thickening agents, adhesives or other additives, otherwise, foaming effect would be affected;

(4) Coating will affect the fastness, so test with small sample before use when coating is added.

(5) Foaming height is decided by the ratio and amount of foaming paste used;

(6) 80 to 100 meshed screen printing should be used

(7) The Quality guarantee period is 6 months under room temperature.

Contact us if you need more details on Foaming Paste. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Foaming Printing、Foaming Ink. If these products fail to match your need, please contact us and we would like to provide relevant information.

Foaming paste A;

Foaming paste B;

Foaming paste C.

I. Properties:

(1) Appearance: light yellow paste

(2) Composition: high molecular polymer and filling compound

(3) Ion type: Negative ion type or Non-ionic type

II. Characteristics

(1) Good foaming effect and excellent stereo sense

(2) Good fastness, soft hand feeling, flat surface

(3) Foaming height: A> B> C

III. Application scope:

It is suitable for printing bulge type pattern on cotton or cotton blended fabrics.

IV. Reference formula:

20 to 50 percent of foaming paste

30 to 40 percent of white glue

20 to 40 percent of elastic transparent glue

5 to10 percent of Pigment Paste

100%

V. Printing processes:

In order to create a better stereo sense, it is necessary to be over printed two times.

I.e.: Printingblow dryingprintingair drying (or baked under moderate temperature) hot pressingfoaming and shaping.

After foaming, it should have a flat surface; the hot pressed foaming pressed is carried out under a temperature of 130 to 150 also for about 5 seconds.

To have a brighter, more lustrous and more elastic effect, you can cover foamed patterns by a layer of overprinted elastic transparent glue mixed with coating.

I.e.: Foaming paste printingblow dryingprintingblow drying---transparent glue plus coating printingblow drying or baked under moderate temperatureheated to foam into final shape.

VI. Precautions:

(1) The printed patterns should not be heated for foaming before they completely dry, otherwise, the fastness and flatness will be affected.

(2) The foaming paste should be made too thin.

(3) Do not add water, thickening agents, adhesives or other additives, otherwise, foaming effect would be affected;

(4) Coating will affect the fastness, so test with small sample before use when coating is added.

(5) Foaming height is decided by the ratio and amount of foaming paste used;

(6) 80 to 100 meshed screen printing should be used

(7) The Quality guarantee period is 6 months under room temperature.

Contact us if you need more details on Foaming Paste. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Foaming Printing、Foaming Ink. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Foaming Paste ABC

Other Products

Hot Products

Water-Based Flexo Ink for Printing From The FactoryElectrostatic Flocking Binder for TextileEnvironment-Friendly Water-Based Metal PaintStone Wash Jeans Elastic White PasteHigh Quality Pigment Printing Thickener for The Chemical MarketThree-Dimensional Hot Stamping/Foil Paste for Cotton FabricWaterproof Nylon GlueFoaming Paste for TextileWater-Based Binder for Textile and TapePgh Glitter Paste Used with Glitter PoederGravure Printing Ink for PE, PP, BOPP Film (APG)Wk-Series Water Based Environmental Protection Glass PaintGravure Printing Ink (LPMAX series)Textile Printing Pigment Color Paste (TH)Environmental Printing Pigment Paste for Various AspectsWater-Based Printing Ink for Texitle/Garment/Fabric